A popular belief not so grounded

Tipolito Moderna is an interesting privately own company located in North-East of Italy, that works in the Graphic Art field manufacturing a wide range of publishing products. In this factory there are offset print, digital and bindery lines.

A consistent part of the production is made by short/medium runs of saddle stitched products, obtained through two stitching lines with gathering machines of 4 and 6 stations, unloaded by hand during three daily shifts. This is a heavy job for the operators, because they are supposed to load the signatures, operate the machine and follow the workflow. At the same time the finished product (which amount to more than 15000 kg per shift) have to be unloaded and palletized, with the consequent operations of inserting slip sheets and preparing the next empty pallet.

A repetitive process, that doesn't justify the use of human resources.

Tipolito Moderna management has decided to move beyond the commonly belief that the end-of-line automation would be effective only if applied on a high intrinsic value products, as large format hardcover or softcover volumes. For this reason they ask Solema to develop a proper solution, as they know that automation is our mission.

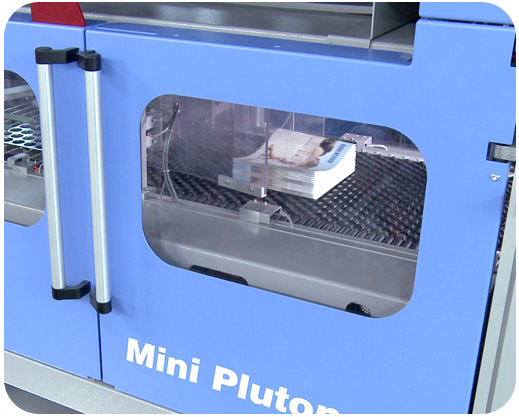

Considering the average production speed and the spaces, it has been easy to understand that Mini Pluton would be the most appropriate solution. By inserting the machine in these spaces with its compact dimensions to ease speed and flows, the company has managed to reach two goals: the first of course is that the job for operators is now easier and lighter, the second is obviously a short return on investment (less than 3 years) as now with Mini Pluton the production speed is higher.

These facts have been so clear that it has immediately justified the investment. This has had as a result the purchasing of another Mini Pluton simultaneously.