On September 15th, 2011 the first big Buffer System, Magic Box and Pluton have been installed at Watchtower Japan.

This installation is considered a milestone for Solema. It is our first approach to the Japanese market. We worked on this project together with Müller Martini, which developed a large Hardcover Automated Bindery Line in conjunction with their main partners, including Solema.

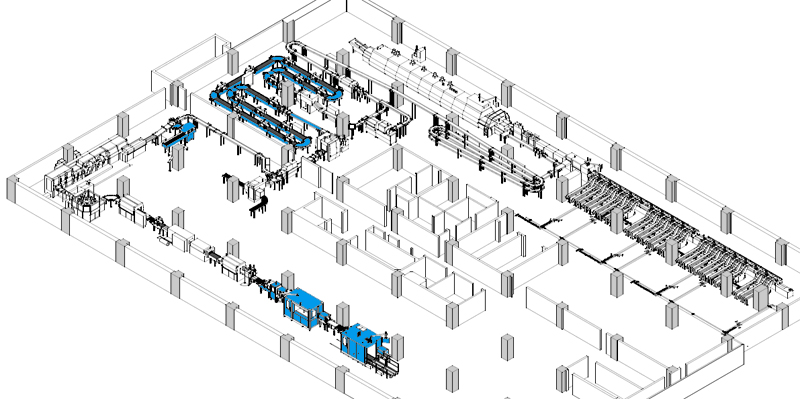

Below is a layout of the entire installation with the highlighted Solema components.

Solema's contribution to this installation included some of our well-known machines:

1) Buffer System that is dynamic andd absorbs the different machine production speeds, as well as the difference in set up times between them. A buffer system, where the products are stacked, is also helping the glue to dry in a minimized space. The dynamic control of the buffer system enables accumulation and releases products when required to ensure continuous production without "empty cycles".

At Watchtower a buffer system includes stacking the various products using Delta ST conveyor, Stacker and De-Stacker that is installed between the binder and the trimmer.

At Watchtower a buffer system includes stacking the various products using Delta ST conveyor, Stacker and De-Stacker that is installed between the binder and the trimmer.

2) Fast Book book block feeder: Fast Book is the feeder that was been developed to be used in a variety of applications. It can be installed on the separating element or hand feeding unit of a perfect binders, book back gluing machine or prior to casing-in machine, in front of shrink wrapper of any kind or anywhere products need to be fed.

At Watchtower in Ebina, the Fast Book with Autoload is used to feed gilded book blocks in the Diamant line after they have been side-gilded on Ochsner machines.

At Watchtower in Ebina, the Fast Book with Autoload is used to feed gilded book blocks in the Diamant line after they have been side-gilded on Ochsner machines.

3) Magic Box automatic boxing machine: Magic Box is built on a very small footprint to allow its application even in tightest spaces. The flexibility of the machine allows for a large range of products that cover all the different sizes of books which are produced worldwide. The make-ready on the Magic Box takes less than 3 minutes and can automatically box 1, 2 or 4 piles in a box.

The Magic Box installed at Watchtower has an automatic pad feeder to feed card boards that are used to fill the boxes, protecting high quality bibles.

The Magic Box installed at Watchtower has an automatic pad feeder to feed card boards that are used to fill the boxes, protecting high quality bibles.

4) Pluton Palletizer: Originally developed to palletize products for the Printing Industry, the Pluton palletizer offers many advantages to the end user for its flexible conception. Main characteristics of the machine: Small footprint which allows its application even in very tight spaces, continuous jogging of the product during throughout the process, linearity and simplicity of the movements. The machine's movements are controlled through servo-motors to enable a simple, but precise control of the functions and the possibility of an automatic size-change. The machine handles piles of soft cover and hard cover products, loose, shrink wrapped, strapped or banded stacks. Boxes, newspapers and saddle stitched products can also be palletized.

The Pluton installed at Watchtower is used to palletize boxes or loose piles of single wrapped bibles, or other products depending on the needs.

The Pluton installed at Watchtower is used to palletize boxes or loose piles of single wrapped bibles, or other products depending on the needs.

We are very proud that we have been chosen to be part of the largest bindery project in Japan in recent history. It was a real pleasure to work with such an efficient and professional team of specialists like those of Watchtower USA, Watchtower Japan and with the Müller Martini organization.