Assembling and gluing into boxes of "U" partitions

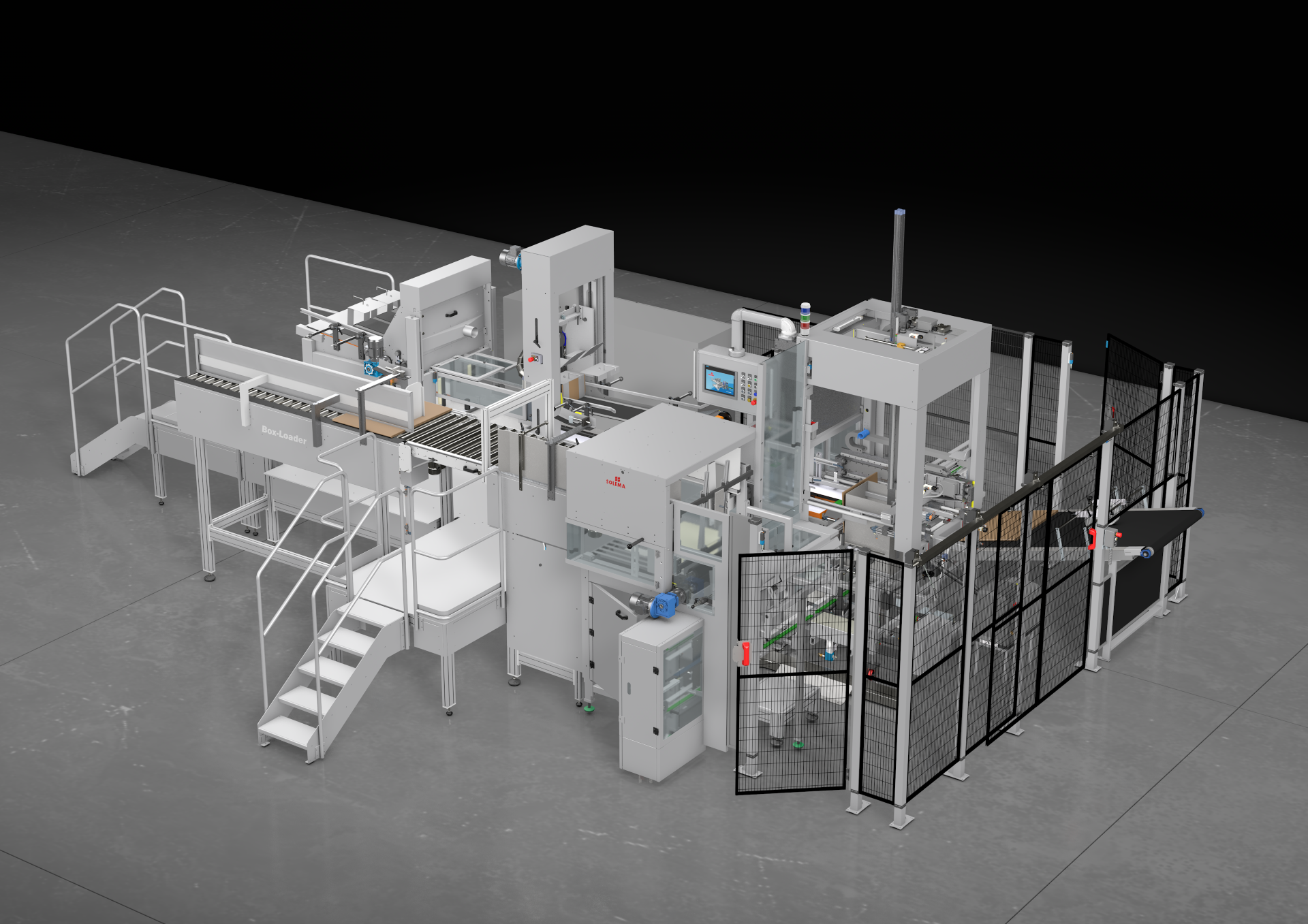

CASIERMATIC has been conceived to answer the increasing demand of automation in the process of assembling, inserting and glue locking of partitions inside preformed boxes, saving for some applications additional hand processing by means of a very flexible, productive, user friendly solution.

The machine, designed for handling accurately a high range of products, is able to assemble partitions (6-9-12-15 cells) made in corrugated board (B-E-F flutes) and even solid board.

Partition’s coupling to the box is assured by hot melt glue shots, on specific points of the partition with special and precise guns. Partition is therefore fixed by means of glue inside the boxes in 1, 2 or 3 spots.

CASIERMATIC is fitted with a PLC with touch screen interface for job setting and to enable the possibility of saving parameters of specific products and recall them in case of a repetitive work. The machine’s set up time is also minimized to the very least thanks to the automatic axis size change (it is possible with the installation of 7 new motors, 1 for each axis).

Technical Data

| Products | B — E — F flutes and solid board fiber |

| Board thickness | min. 0.7 mm (1⁄32”) |

| "U" element width | min. 380 mm (14 31⁄32”) — max. 850 mm (33 15⁄32”) |

| Transversal element width | min. 160 mm (6 5⁄16”) — max. 330 mm (13”) |

| "U" element lenght | min. 160 mm (6 5⁄16”) — max. 395 mm (15 9⁄16”) |

| "U" element height | min. 160 mm (6 5⁄16”) — max. 340 mm (13 3⁄8”) |

| Machine throughput | max. 25 boxes/minute |

| Optional devices available | Automatic box loader |