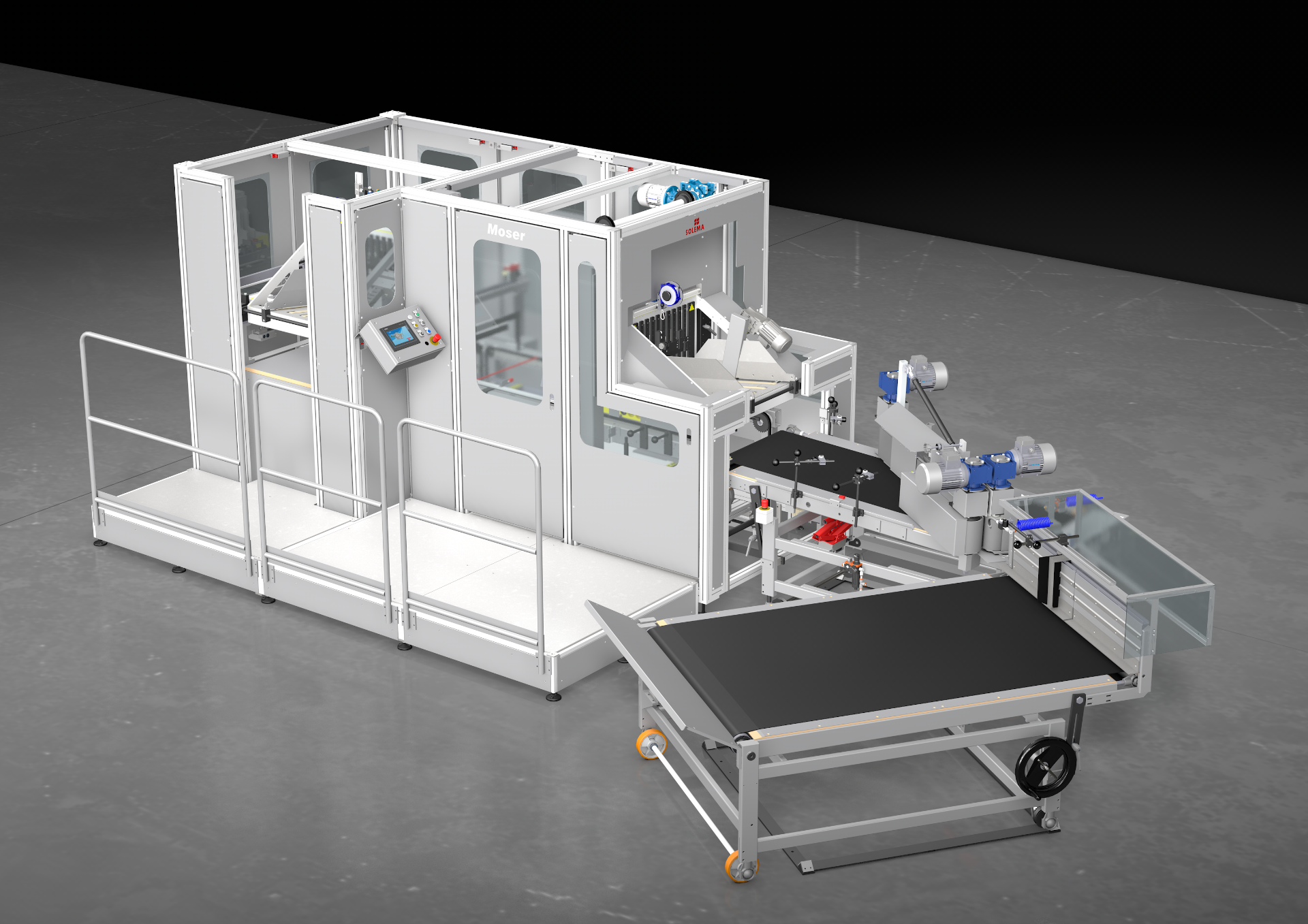

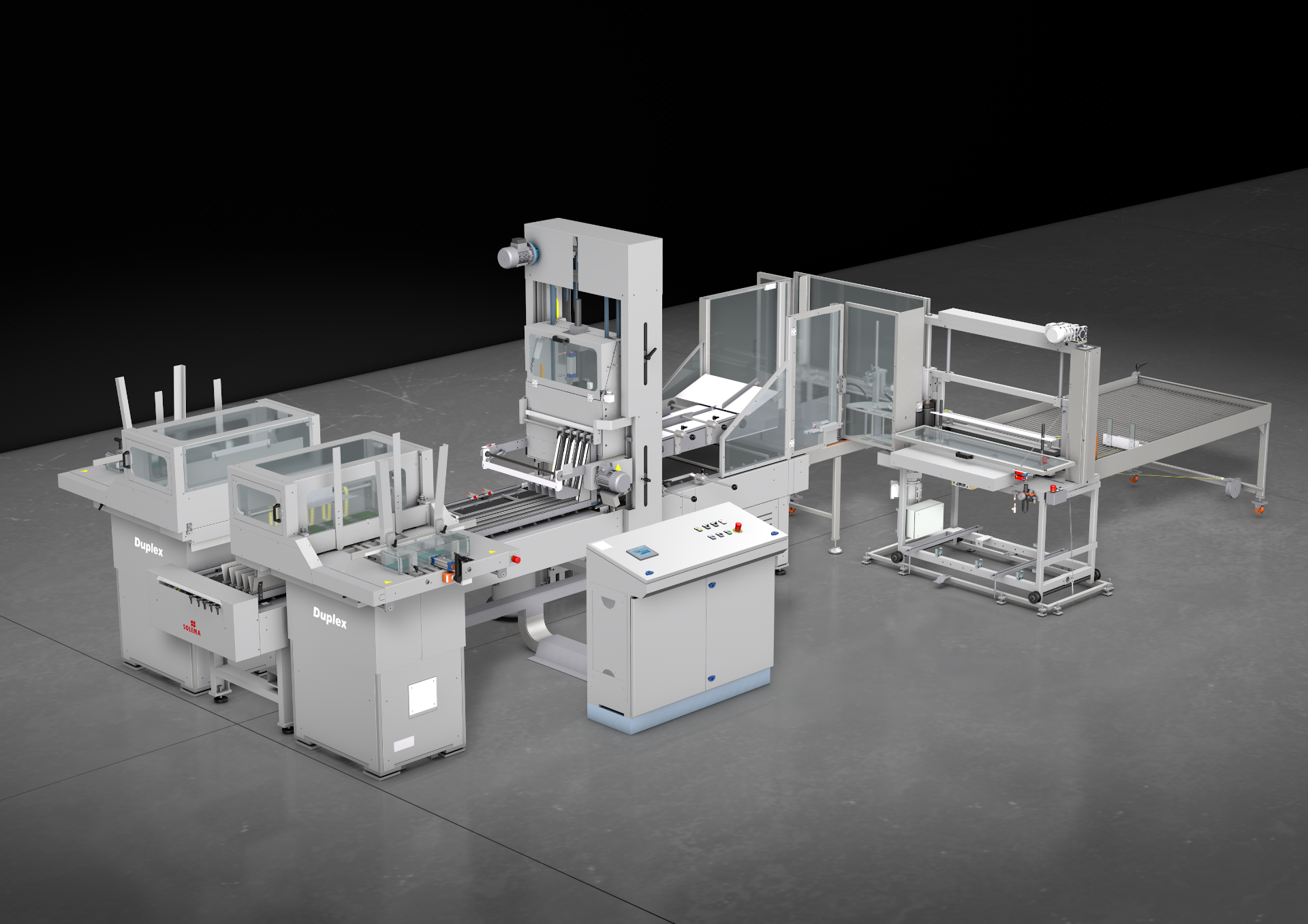

Compact and versatile: Andax automatic partition assembler

Solema Andax is ideal for companies seeking compact, high-speed solutions for assembling partition paper. Designed to optimize efficiency and reduce downtime, these machines ensure precise and reliable handling of various partition elements formats. Their key advantages include:

- Fast setup times and intuitive operation

- High assembly speed, even in small spaces

- Adaptability to different layouts

- Minimal mechanical adjustments for format changes

Perfect for manufacturers with limited floor space or frequent job changes, Andax guarantees flexibility, precision, and consistent performance.

.jpg)