Key considerations for the selection

When selecting a cardboard cutting machines supplier, especially for large-scale operations, it's crucial to focus on several key factors that can significantly impact your business. First and foremost, consider the machine's ability to offer both high-volume production and the precision required for intricate or custom designs. A top-tier supplier should provide equipment that not only scales with your production demands but also delivers flexibility, allowing you to easily switch between various product types and sizes without sacrificing efficiency.

Another vital aspect is operational efficiency. The best machines are engineered to reduce downtime and minimize material waste, ensuring that your production line runs smoothly and with minimal interruptions. This translates to cost savings, not only through optimized material usage but also by lowering labor and maintenance costs over time. A reliable supplier will prioritize innovative technology, ensuring that their machines integrate seamlessly with your existing systems and are future-proofed for evolving industry needs.

In addition to these technical advantages, a strong cardboard cutting machine supplier should offer robust after-sales support, including maintenance, spare parts availability, and technical expertise. This ensures that your investment remains productive and sustainable in the long run, making the right choice in machinery essential for long-term profitability and growth.

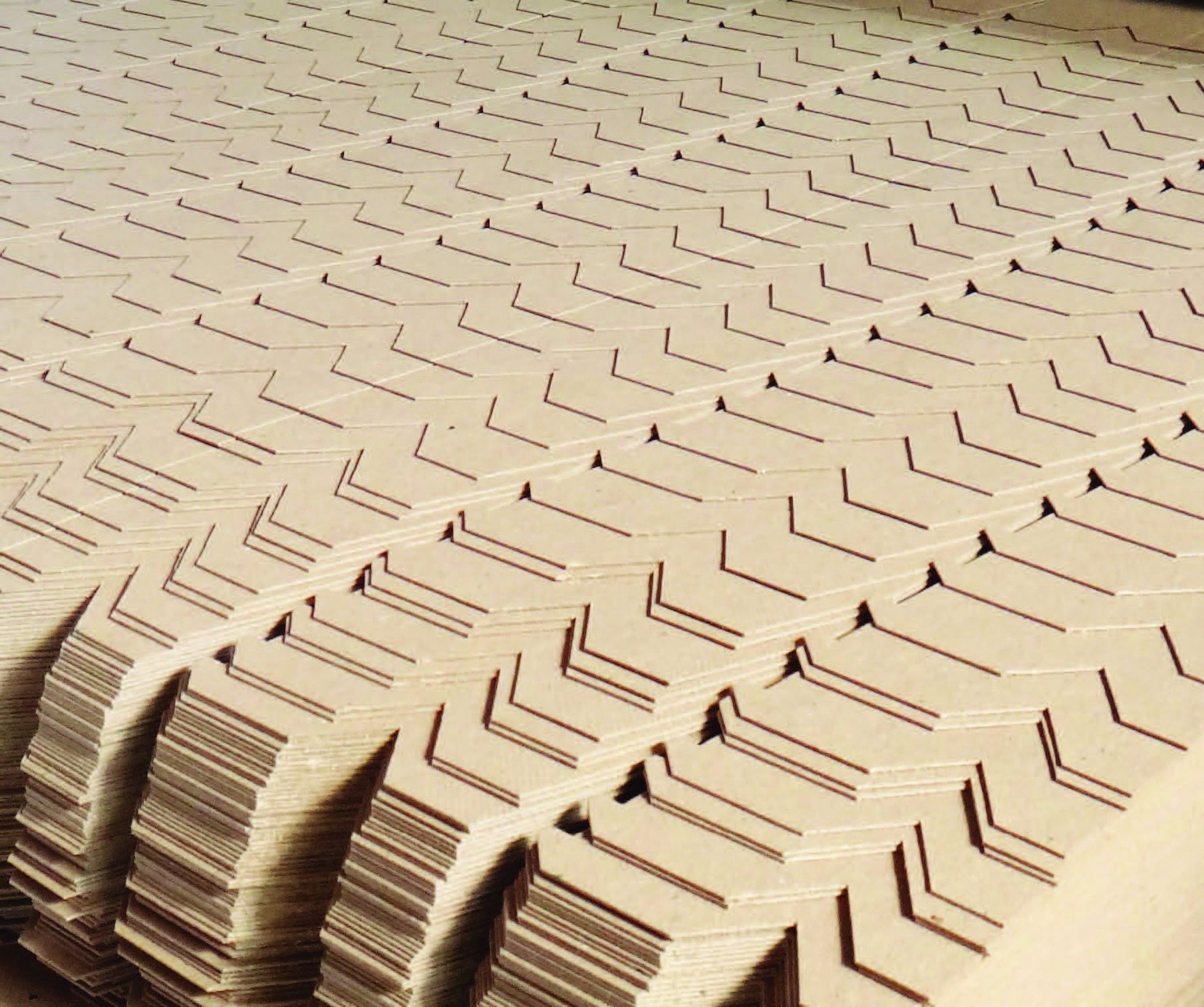

As a leading cardboard cutting machines supplier, we at Solema specialize in providing high-quality, custom-built solutions that meet the unique needs of our clients. Our machines, meticulously designed and produced in-house, offer unmatched flexibility and precision, allowing businesses to optimize their cardboard cutting processes. From creating custom-sized boxes to ensuring high-precision cuts for intricate designs, our cutting machines empower businesses to reduce waste, save costs, and boost efficiency. Our advanced technology, combined with years of expertise, ensures that we are the go-to supplier for companies looking to streamline their cardboard production operations.