Our company was born in 1982 by the need of our customers to get in touch with specialist suppliers, able to realize con-veyor systems used in the graphic industry.

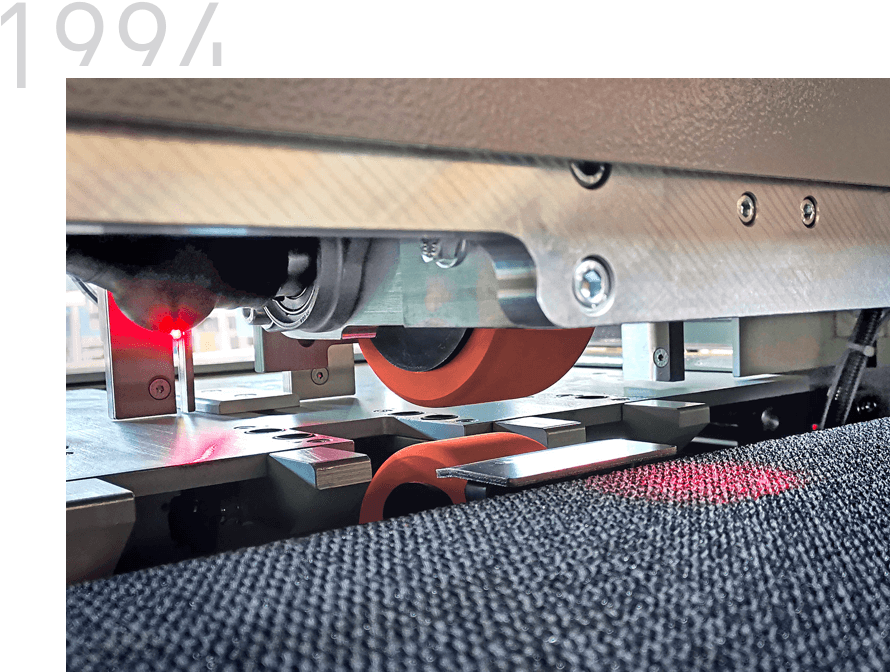

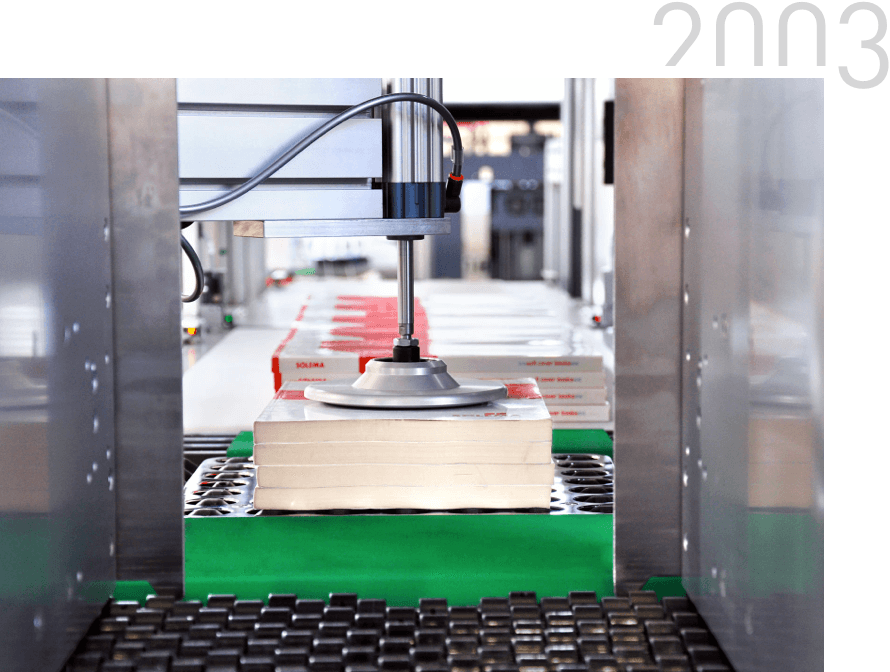

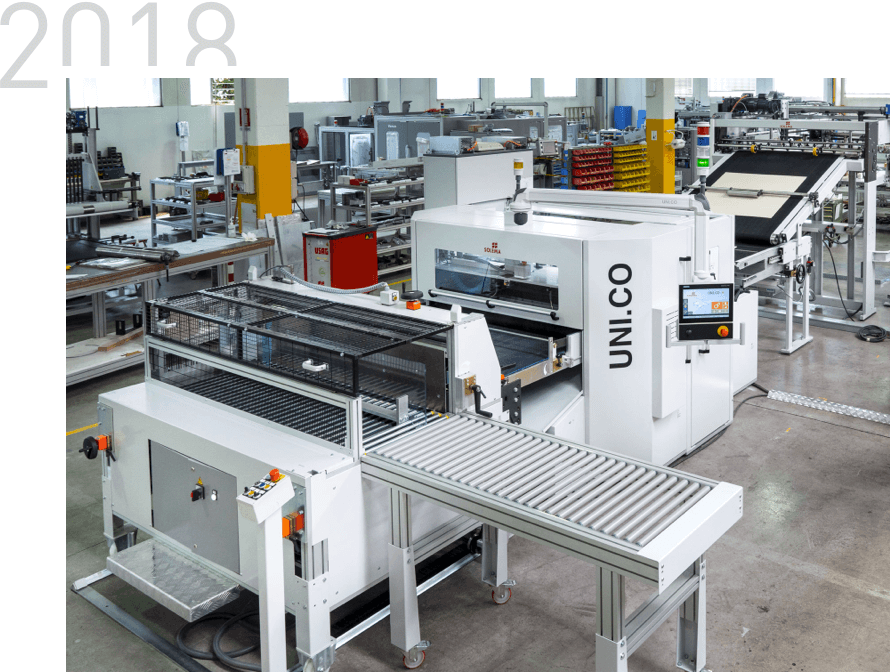

Nowadays Solema is the leader company in industrial automation that proposes innovative machines in graphic art and paperboard converting.

All our products are studied and designed internally by our technical office. High integration allows us to use elements and components realized inside our company: the electrical devices and the software of the machines are developed by our engineers, as well as the electric power units installed on the machines.

The internal management of design, production and assembly allows us a complete control on the productive process, and the constant collaboration between the technical and the sales department guarantees solutions able to meet the industry's three crucial needs: optimize resources, optimize spaces, optimize times.

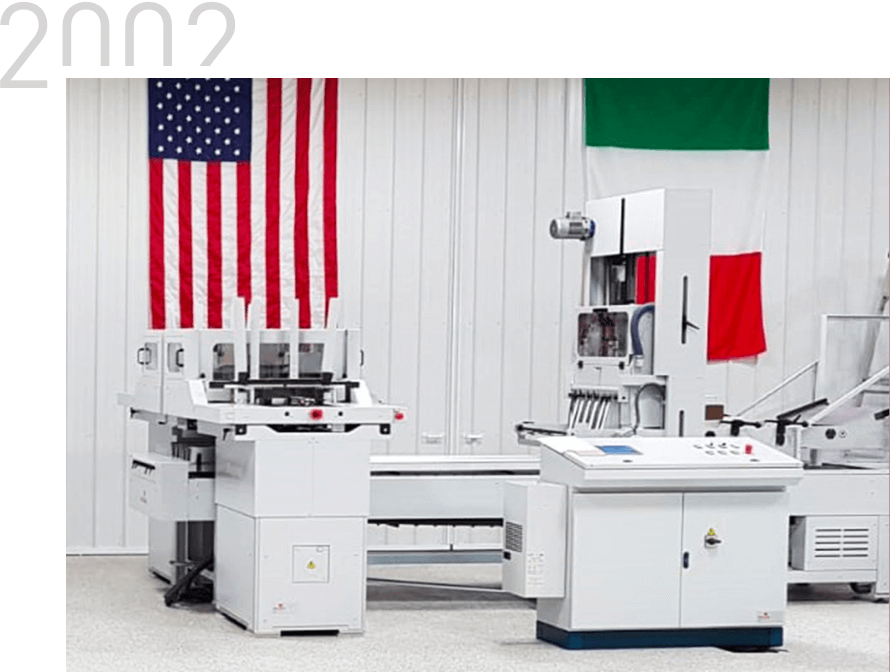

On 2002 we opened a sister Company in North America, in the Midwest (Crawfordsville, Indiana) to provide sales, installations, spare parts and services for all our North American customers.

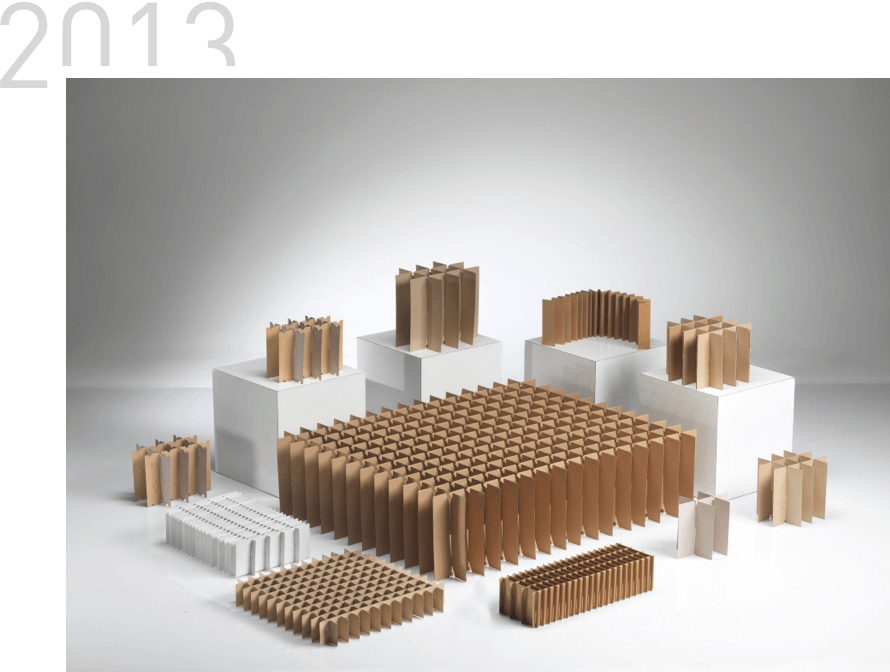

The location has proven to be very well chosen, also in 2013 when we acquired the business unit of the company Roda manufacturing machinery for paperboard pads and partitions.

Solema USA is today the sales coordinator for the full Solema product range in the North American market for both Graphic art and Paper Board Industry.