Efficiency, safety and smart logistics through streamlined robotic palletizing automation

As logistics evolve and workloads increase, many companies are beginning to question whether it’s time to rethink how the final stages of production are handled. Could robotic palletizing automation be the answer?

Reduced labor costs, increased productivity, and improved consistency are just a few of the benefits driving the shift. The conversation is gaining momentum across industries aiming for smarter, safer, and more scalable operations.

Why automate palletizing?

Manually stacking goods on pallets is a repetitive, time-consuming and physically demanding task, often exposing workers to fatigue and injury. As companies scale operations and deal with labor shortages, these traditional methods are becoming increasingly unsustainable. That’s why more companies are reevaluating their end-of-line processes.

Robotic palletizing automation offers a smarter, more efficient alternative. These systems are reshaping production by delivering:

- Improved throughput and faster cycle times;

- Reduced human error for more consistent output;

- Enhanced workplace safety by minimizing physical strain on operators.

From food and beverage to publishing and packaging, the shift to automation is underway. Companies like Solema, which specialize in customized, high-volume palletizing solutions, are leading this transition with innovative, modular systems tailored to specific production needs.

Smart stacking solutions

Automation systems are increasingly being used to improve efficiency in industries that handle repetitive and high-volume tasks. Robotic palletizing is one of the areas where this shift is most evident. In sectors like graphic arts and paperboard, robotic palletizing has become an effective way to optimize end-of-line operations. These systems can integrate seamlessly with upstream equipment - such as stackers - supporting a continuous and reliable production flow.

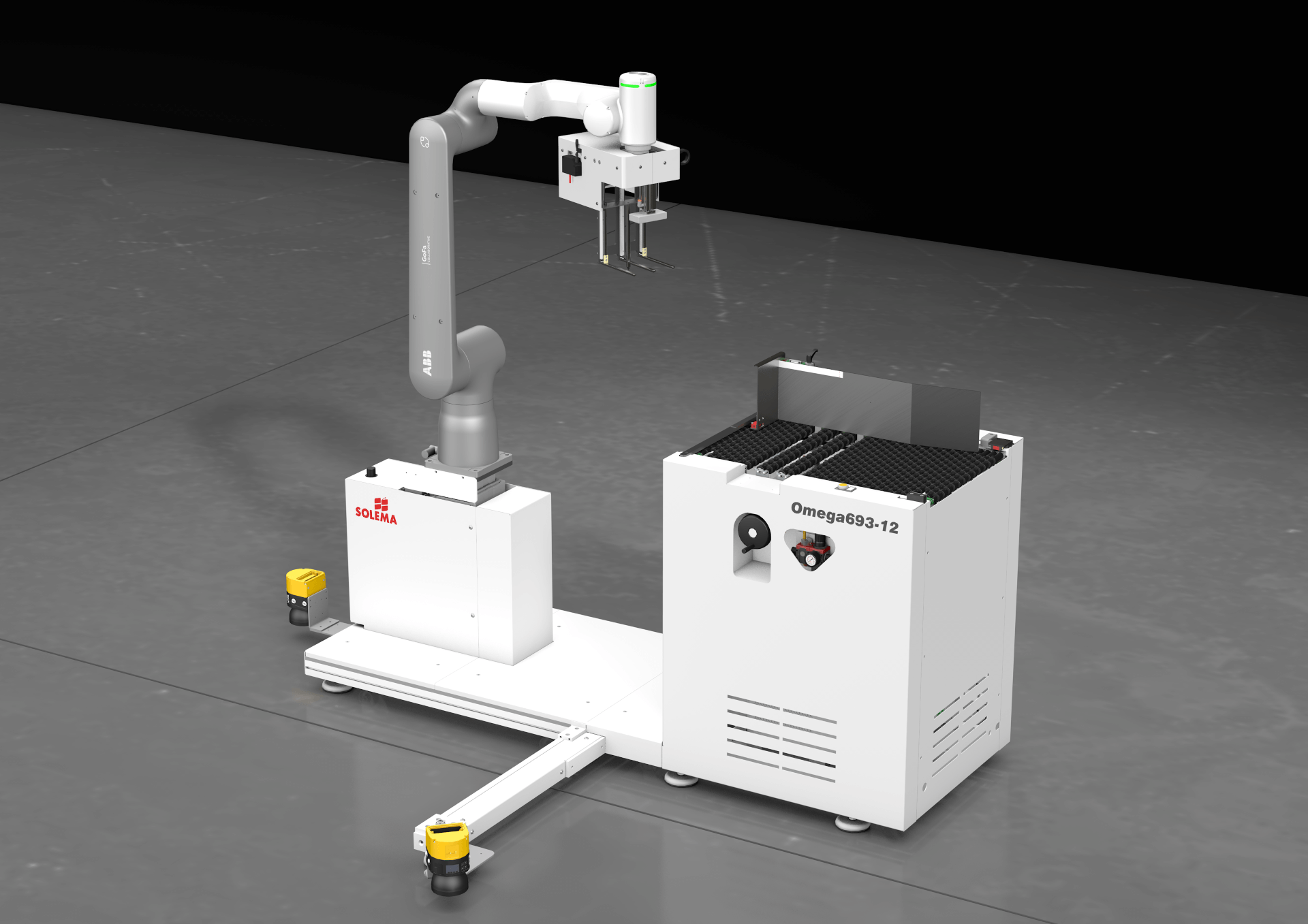

Solema has developed modular solutions that prioritize flexibility, space optimization, and ease of use, such as OMEGA 693 robotic palletizer an automatic machine with an anthropomorphic arm and its respective pick-up station. With over 40 years of experience, the company provides customizable systems suited to both small and large production runs. Their approach focuses on practical integration, aligning with the real-world needs of modern manufacturing environments.

If you want more information about Solema’s robotic palletizing automation, browse our catalogue for automatic palletizers for graphic arts and contact us to request a quote.