Precision, automation, robust mechanics and flexible configuration define a great partition die-cutting machine. But there’s more to consider

In industrial packaging production, a partition die-cutting machine plays a key role. It helps stabilize and protect products during shipping. From corrugated cardboard to paperboard, the accuracy and speed of these machines help manufacturers meet increasing demands for customized, sustainable packaging.

But what really defines a high-performing machine? Let’s dive into what you should look for and why Solema makes the difference.

Why partition die-cutting machine matter?

Beyond the basic functionality, a quality partition die-cutting machine should guarantee repeatable accuracy, reduced setup time, and high output. Here’s what to look for:

- precision cutting: clean and consistent edges with minimal material waste;

- automated setup: for a smooth and quick switch between formats to reduce downtime;

- robust mechanics: reliable performance in demanding industrial environments;

- flexible configuration: to handle different sheet sizes, materials and design.

Partition die-cutting machines support the production of protective dividers for items like glassware, cosmetics, and electronics. Their ability to adapt to different materials and production volumes makes them indispensable across many industrial packaging lines.

While many systems can handle basic operations, the best ones go further allowing packaging manufacturers to scale production efficiently and reduce waste.

Why choose Solema Solutions

A tailor-made partition die-cutting machine is what truly defines high performance. Solema is known globally for developing innovative solutions for the paperboard, bookbinding, and packaging industries. Why are our machines different?

We combine the excellence of Italian engineering with decades of field experience delivering both flexibility and quality. Our machines stand out for their modular design, intuitive user interface, and custom automation options.

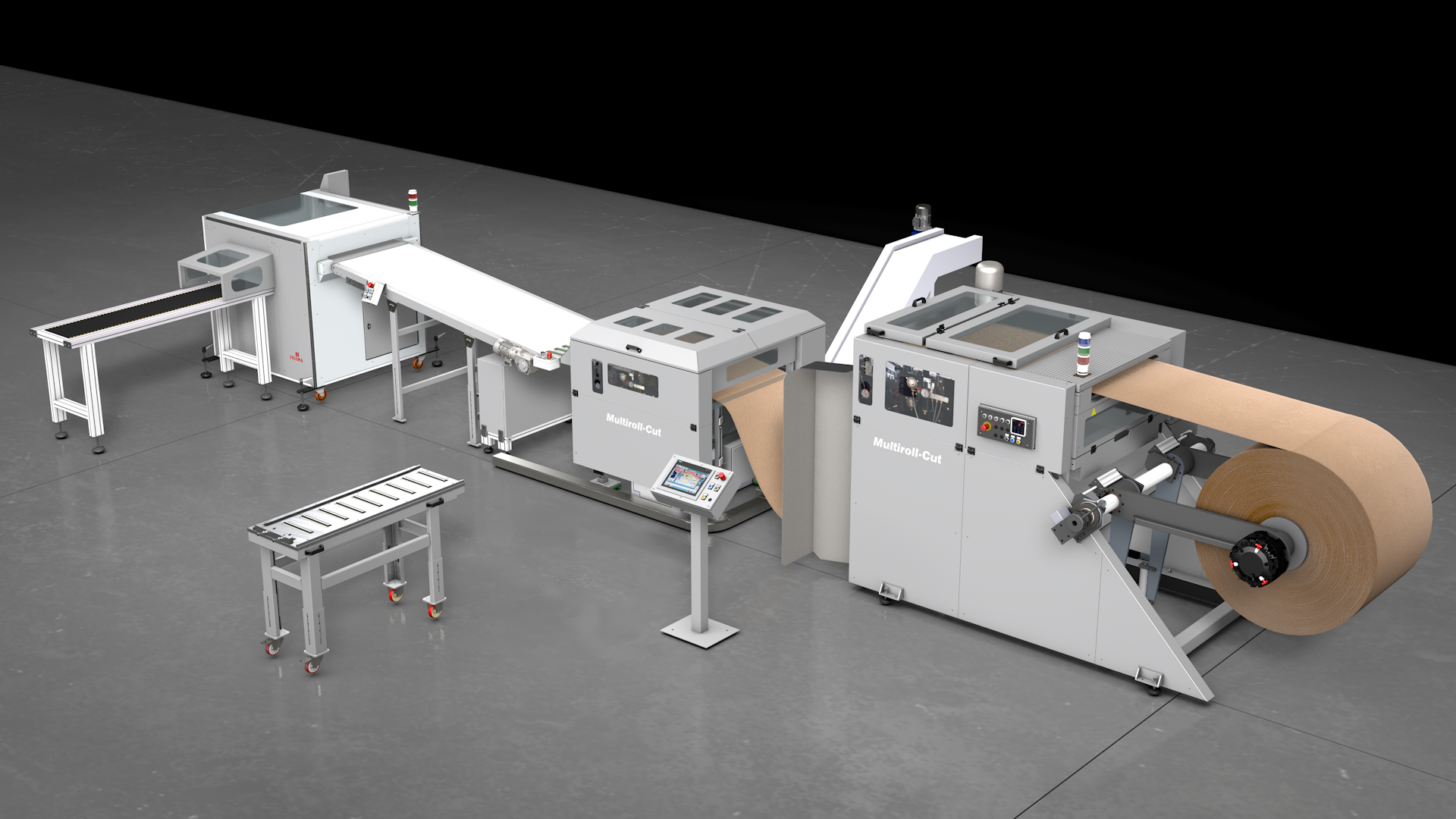

MULTIROLL-CUT designed to integrate seamlessly into the workflow of small and large industries. This die-cutting machine is ideal for high-volume runs and is engineered to handle a variety of paperboard materials. Additional features like remote diagnostics, low maintenance requirements, and fast job changeover further enhance productivity.

With Solema, you’re investing in a long-term partner that understands your industry challenges and designs machines to solve them. If you want more information about our partition die-cutting machine, visit our website and contact us to request a quote.