The benefits of automation packaging systems in modern production include improved quality, greater safety and faster processes

Packaging is much more than a simple protective shell. It preserves the product’s integrity during transport and represents the very first touchpoint between company and customer. Whether it’s a stack of books, an industrial component or a bottle crate, packaging must combine product safety and the ability to communicate reliability.

Businesses recognize that packaging efficiency and quality can influence both customer trust and satisfaction and operational performance. From reducing transit damage to ensuring uniform presentation, the packaging stage is a crucial link in the production chain, one that deserves careful planning and the right technology to scale the business.

Manual vs. automation packaging systems

When comparing manual packaging with automation packaging systems, both approaches have their pros and cons.

Manual packaging systems are often valued for their simplicity and adaptability. They typically involve lower initial costs, allow quick adjustments for unique or custom orders and the human touch can be crucial with fragile products. However manual work also comes with slower pace, limited throughput, higher labor expenses as volumes increase. Scaling up production under these conditions can be really challenging.

Automation packaging systems deliver higher speed and continuous operation without fatigue. They guarantee consistent quality, integrate smoothly with other industrial processes, improve safety and cut down waste.

In bookbinding sector manual methods are not efficient and cost-effective compared with automation packaging system.

How to choose the right system

Selecting the right machines requires balancing production needs, product type and long term efficiency. Some criteria to evaluate include:

- Flexibility and adaptability: ability to handle different product dimensions such as stacks of books or cases

- Space optimization: compact designs that integrate into existing layouts

- Gentle handling: essential for fragile or high-value goods

- Throughput capacity: matching current demand with room for growth

- Integration: smooth connection with conveyors, feeders, or digital systems

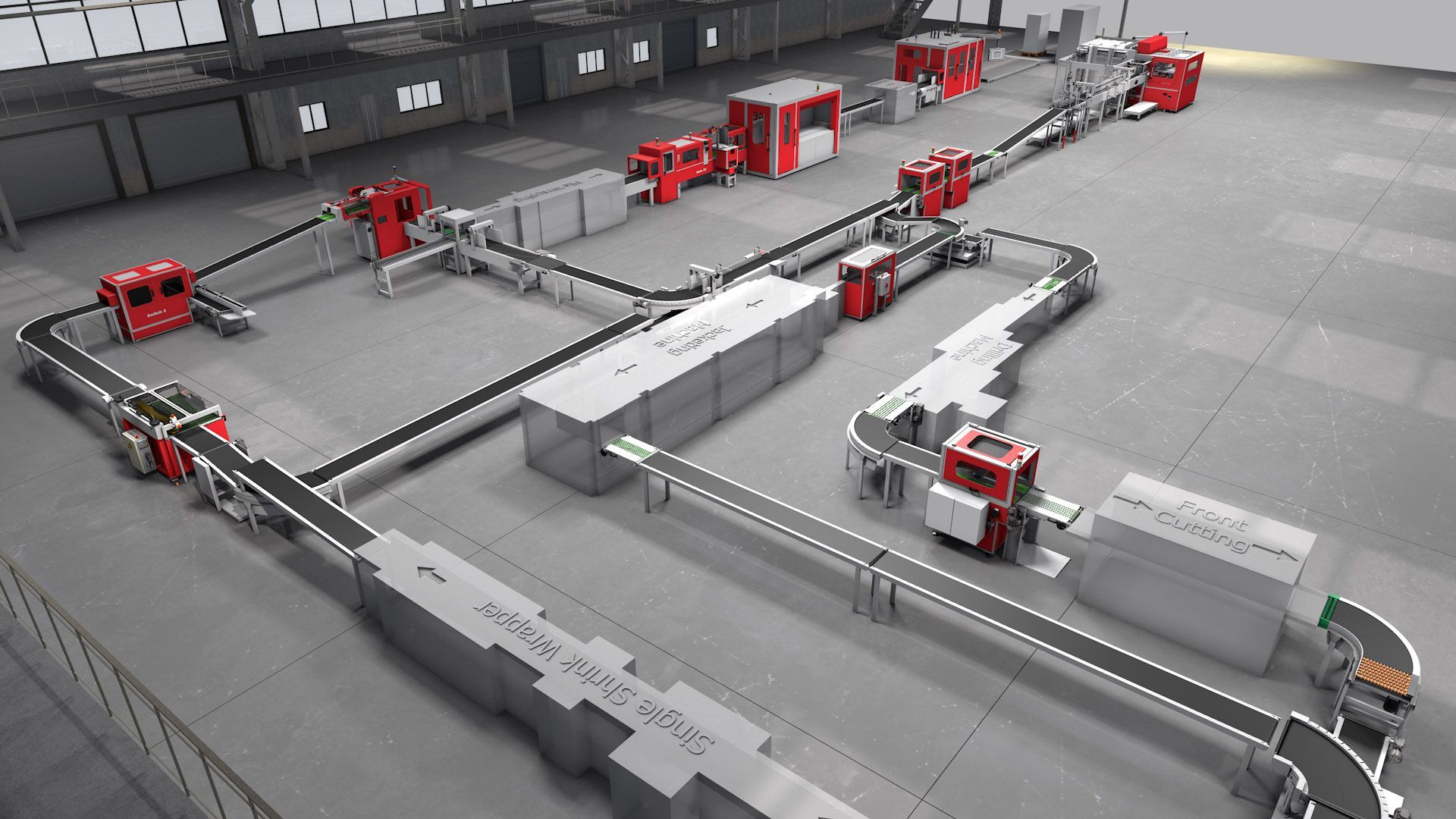

For industries dealing with books and boxes, solutions must guarantee both gentle handling and stacking accuracy. This is where Solema stands out. Our Packaging Line is an industrial processing solution specifically dedicated to the Finishing phase in the Graphic Arts sector.

Solema designs and manufactures advanced machines from palletizers to feeders and stackers, entirely in‑house ensuring full control over each component. Our systems are compact, reliable and engineered specifically for publishing, packaging and paperboard sectors.

To learn more about our automation packaging systems, visit our website and contact us to request a quote.