UNI.CO

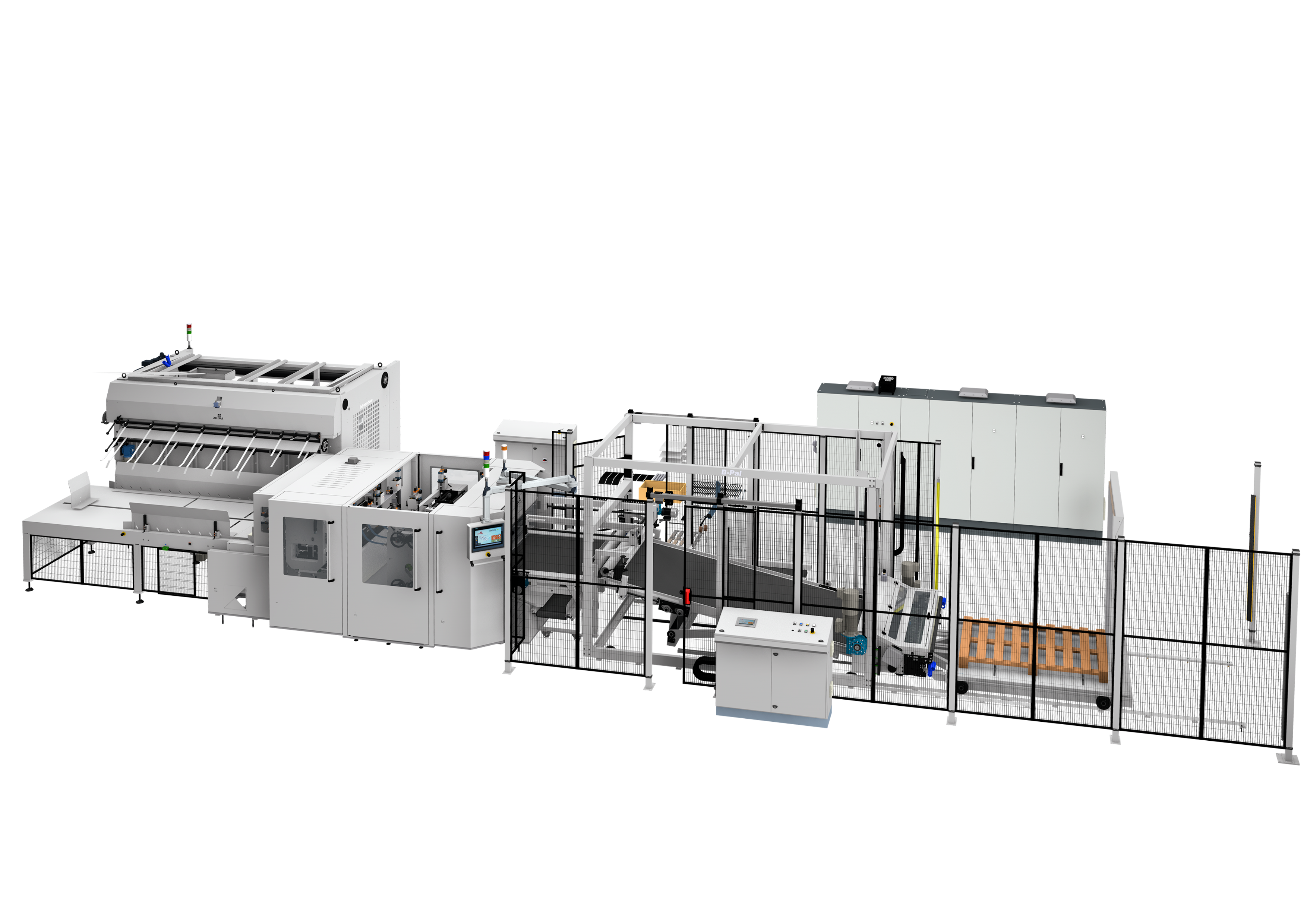

Uni.Co is the most innovative universal cutting system in the converting world and it will guide your business growth at every steps.

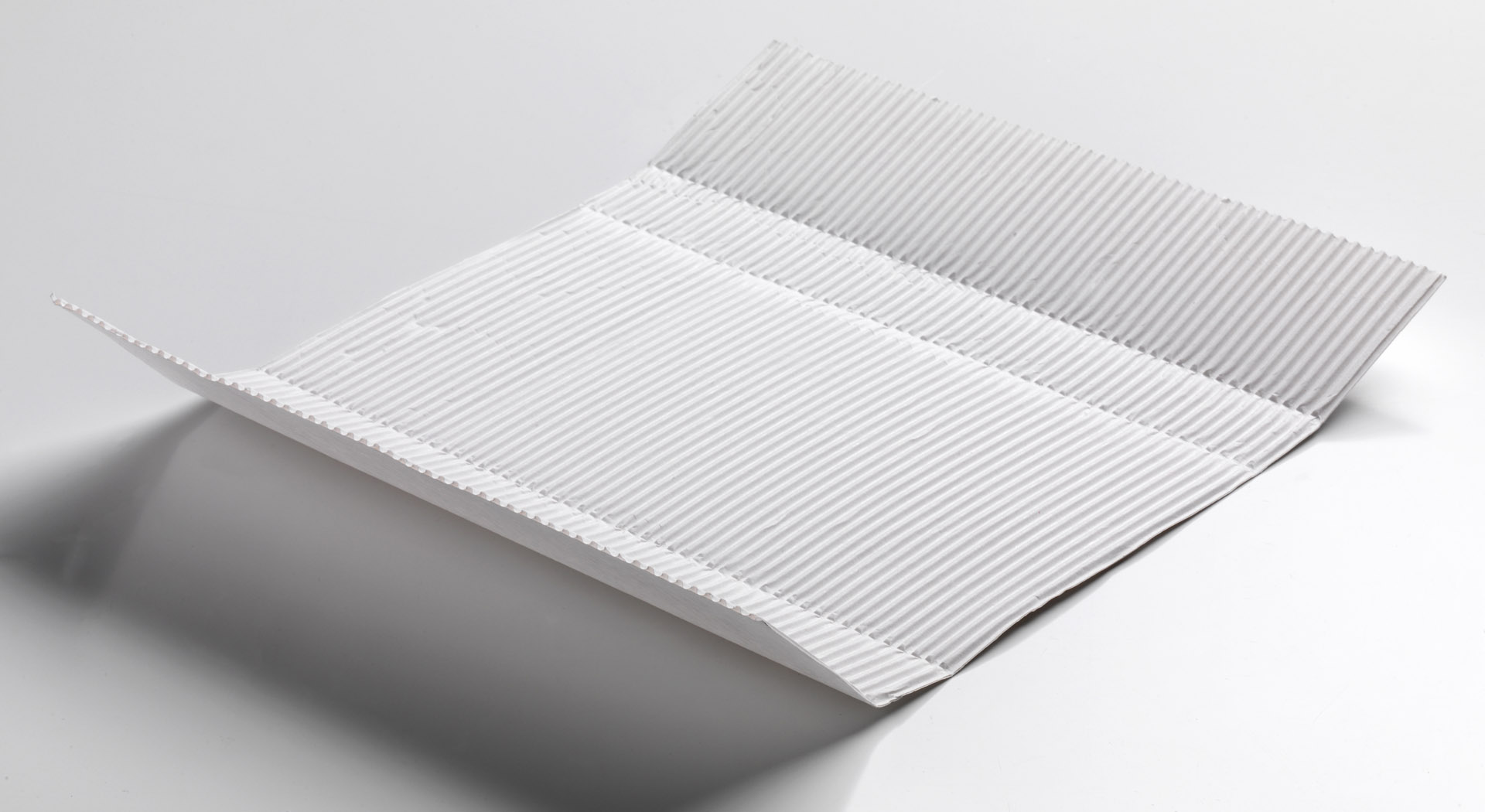

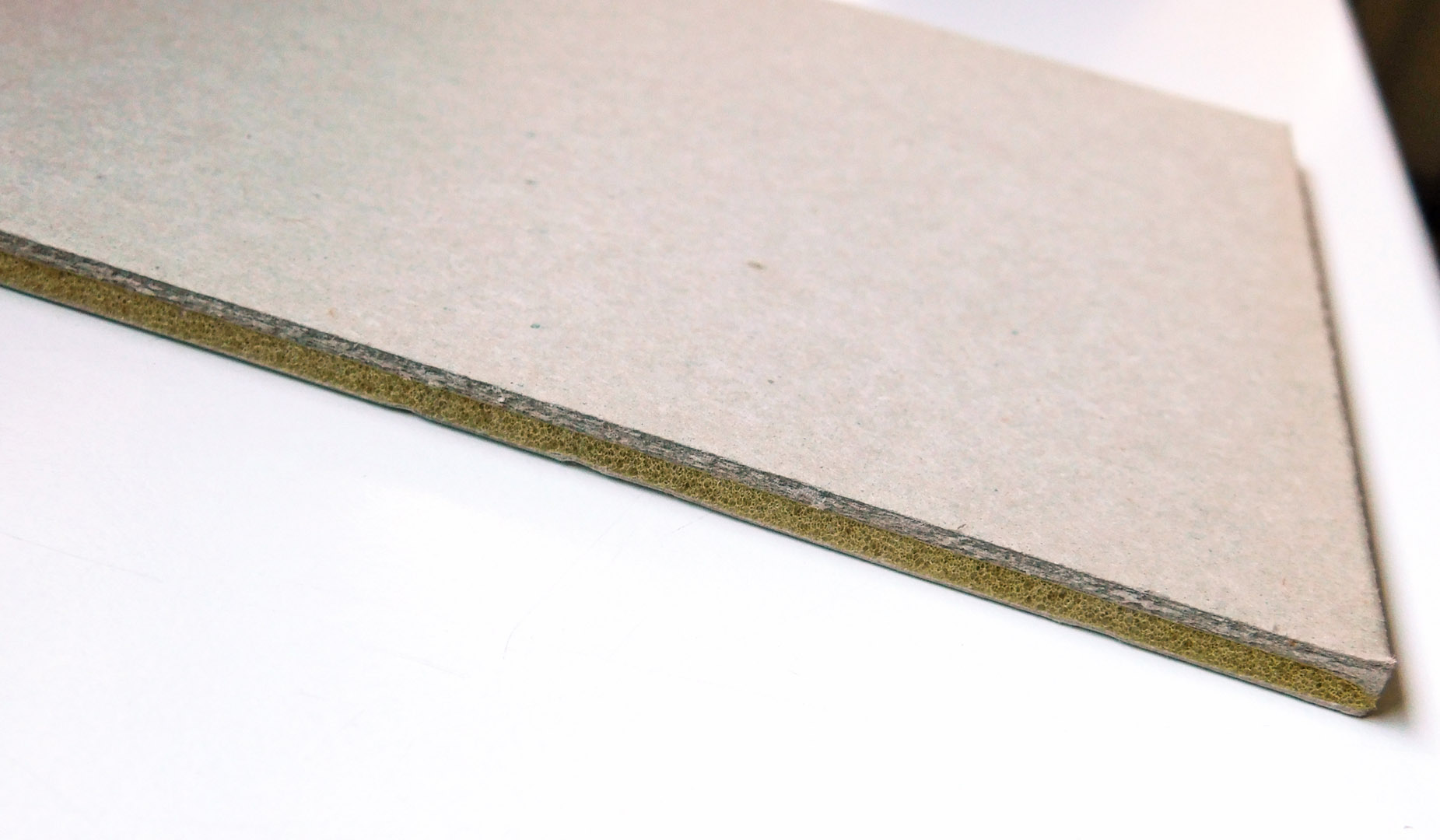

Uni.co is the perfect solution to whom works in the converting industry: it can work with every kind of paperboard, starting from solid or corrugated paperboard’s sheets or reels.

The Uni.co’s modular cutting system is made by different cutting units that assembled together can offer 4 different configurations. Thanks to its modular design this cutting line can develop at any time by adding an extra cutting module, passing from one configuration to another and allowing the company to expand its production.

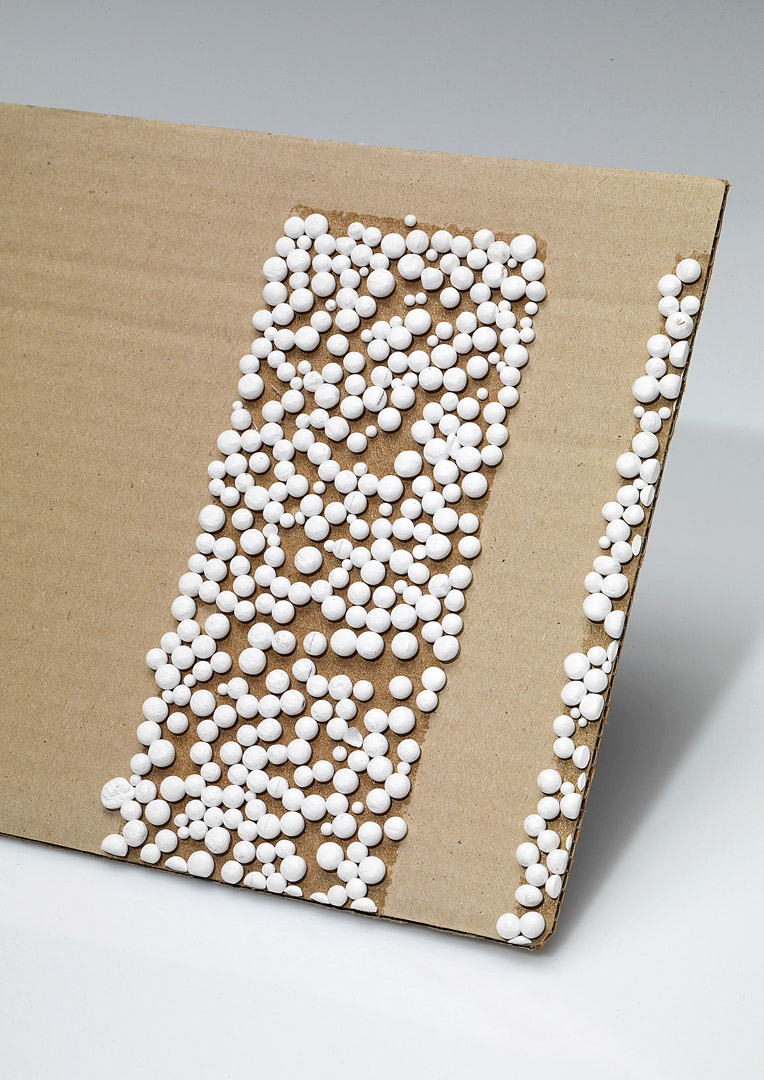

Switching from the production of solid and corrugated paperboard pads to the production of partitions is just a matter of software switches with the new modular Uni.Co. By adding the punching module to the basic configuration I, the customer will have a completely new machine, which turns into configuration F.

This modularity gives two huge advantages:

- Scalable investment thanks to a super technological and innovative machinery.

- Increase the products offer by adding cutting modules easily thanks to machine’s design that allows to update it both from a mechanical and software point of view.

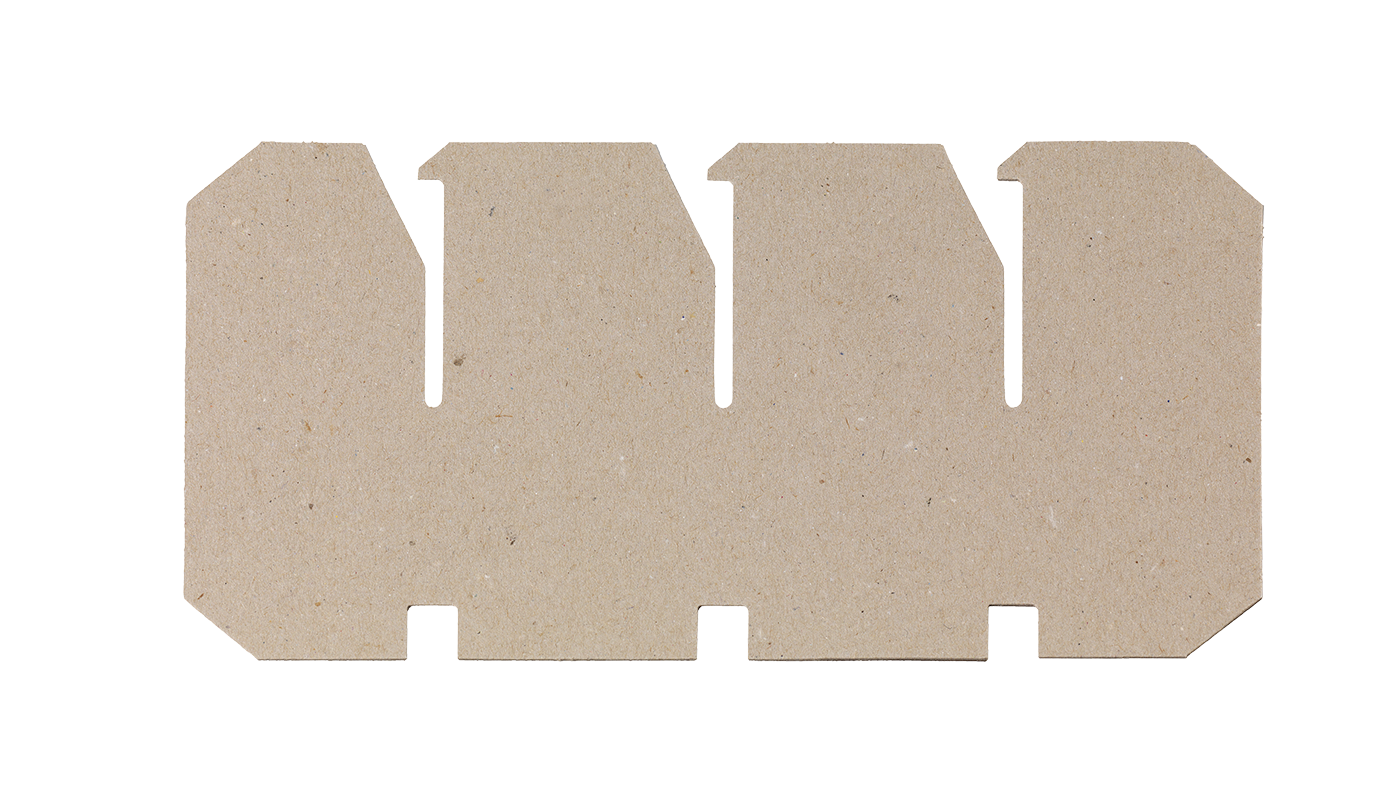

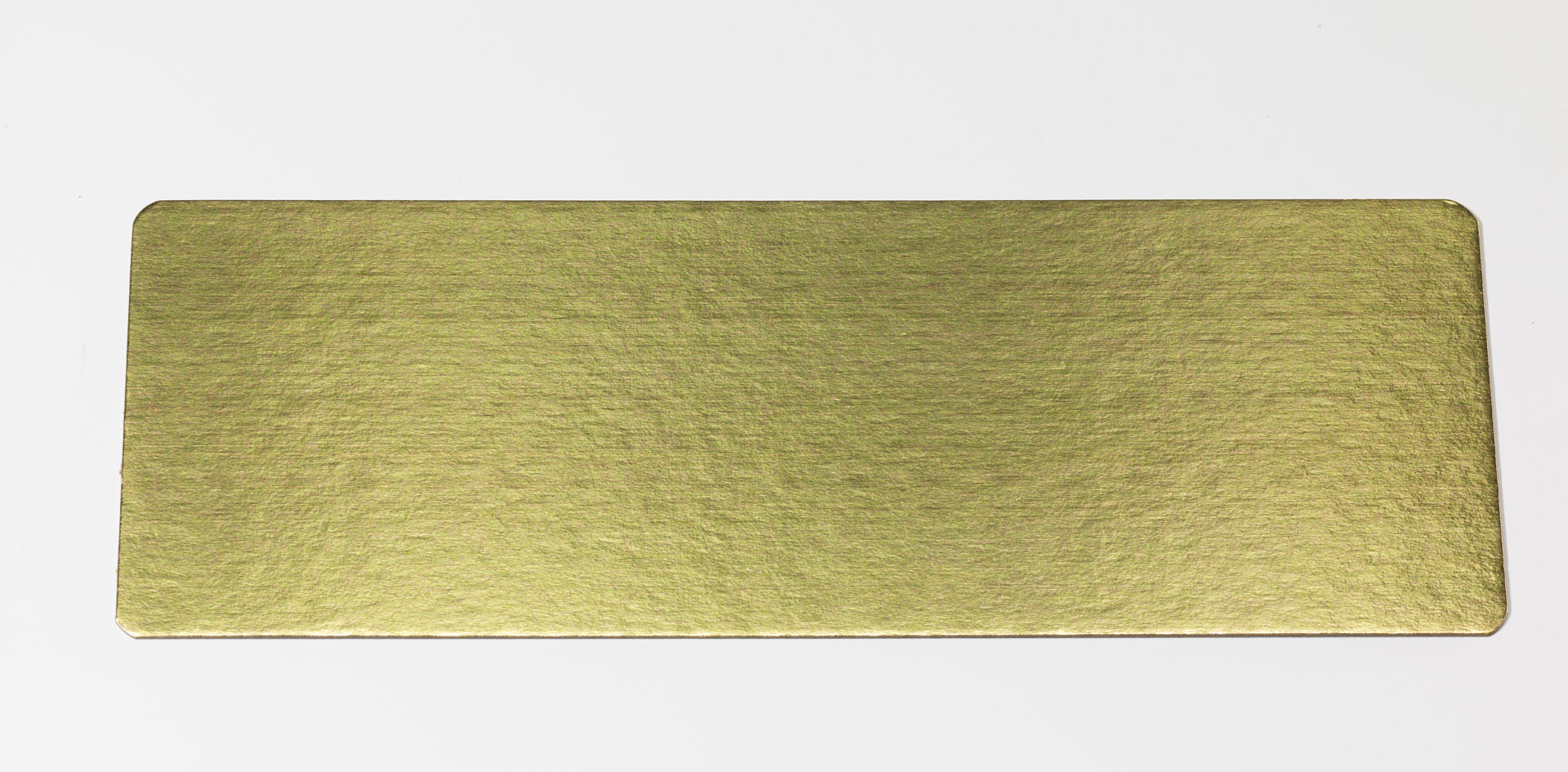

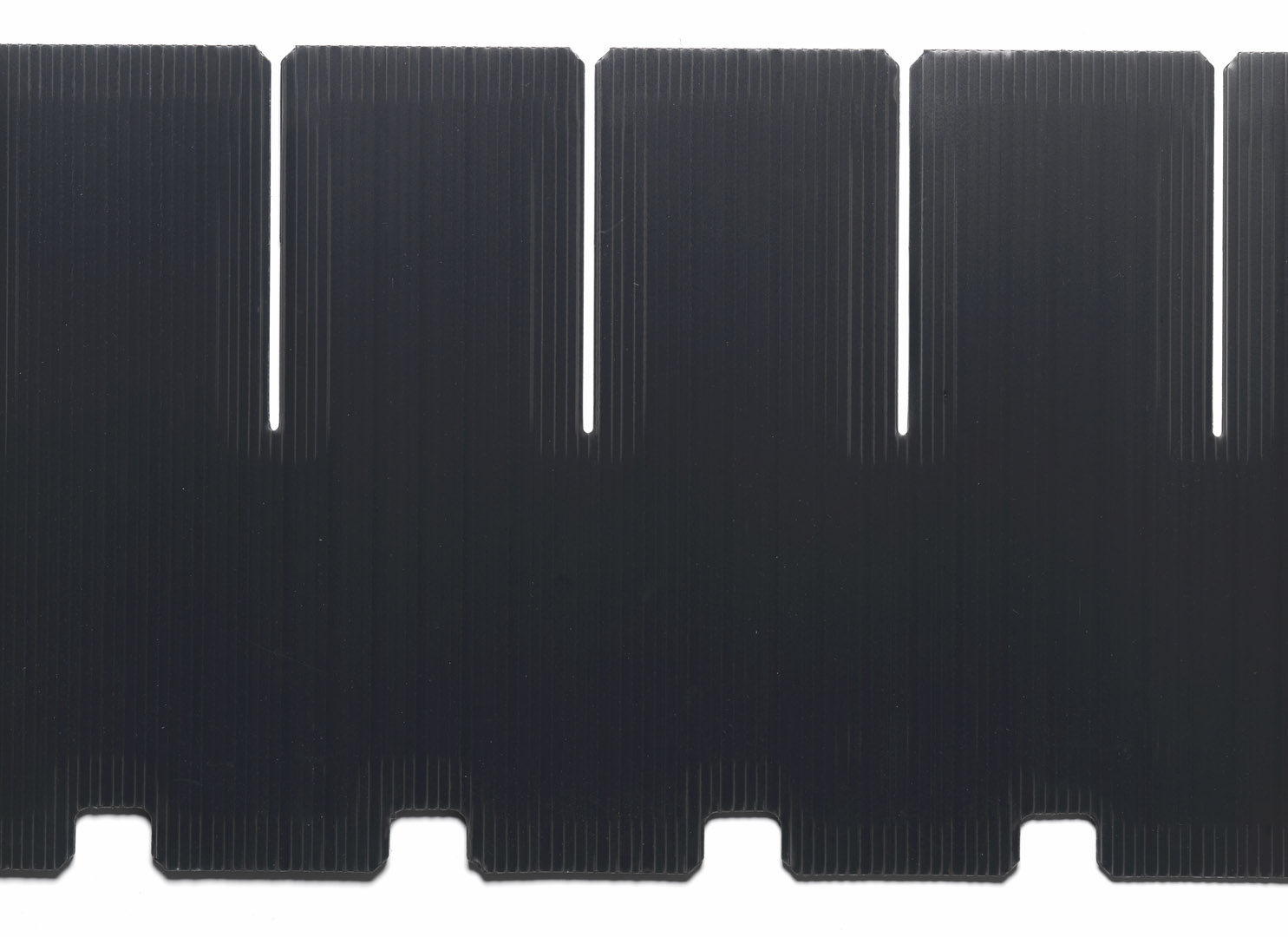

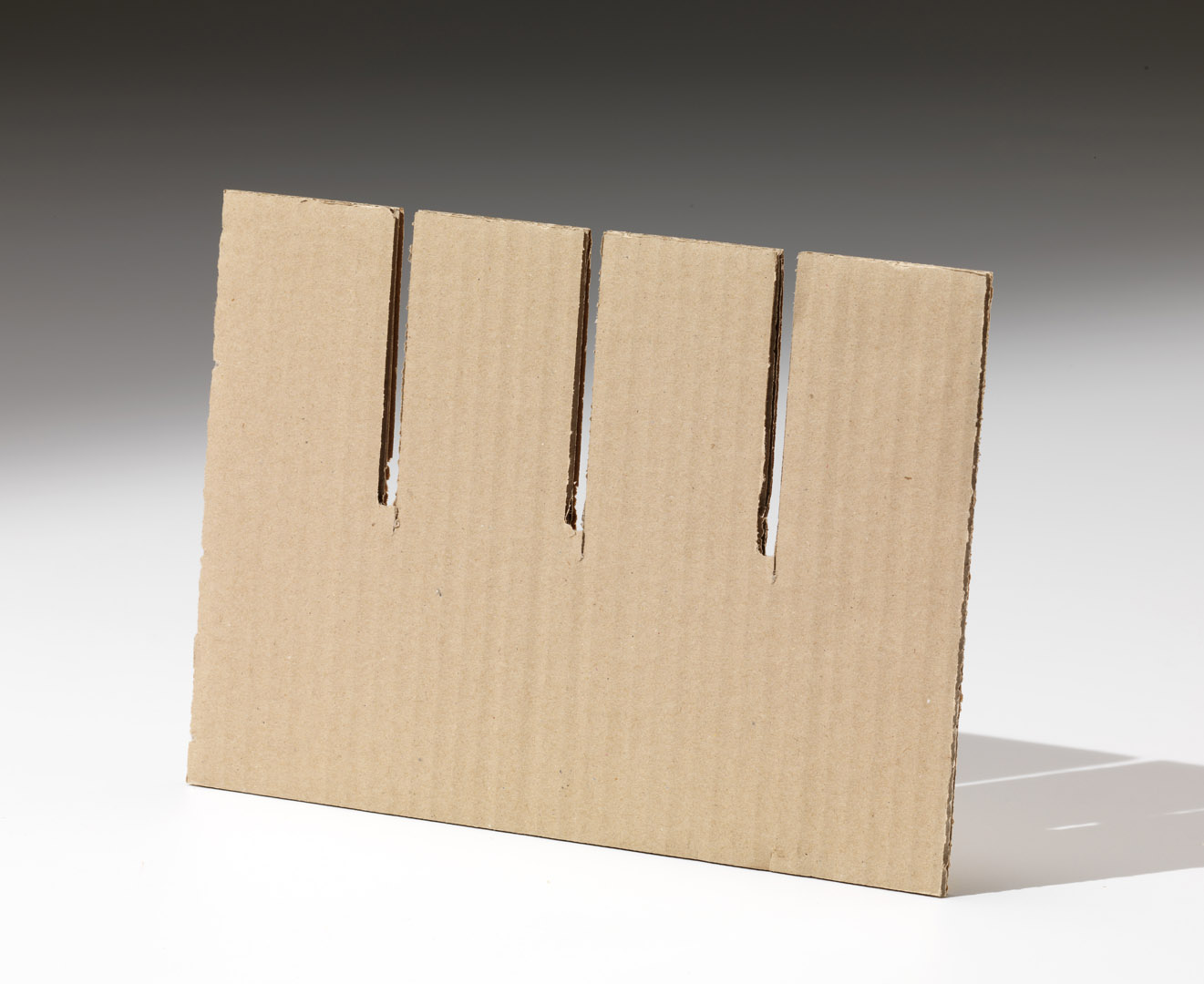

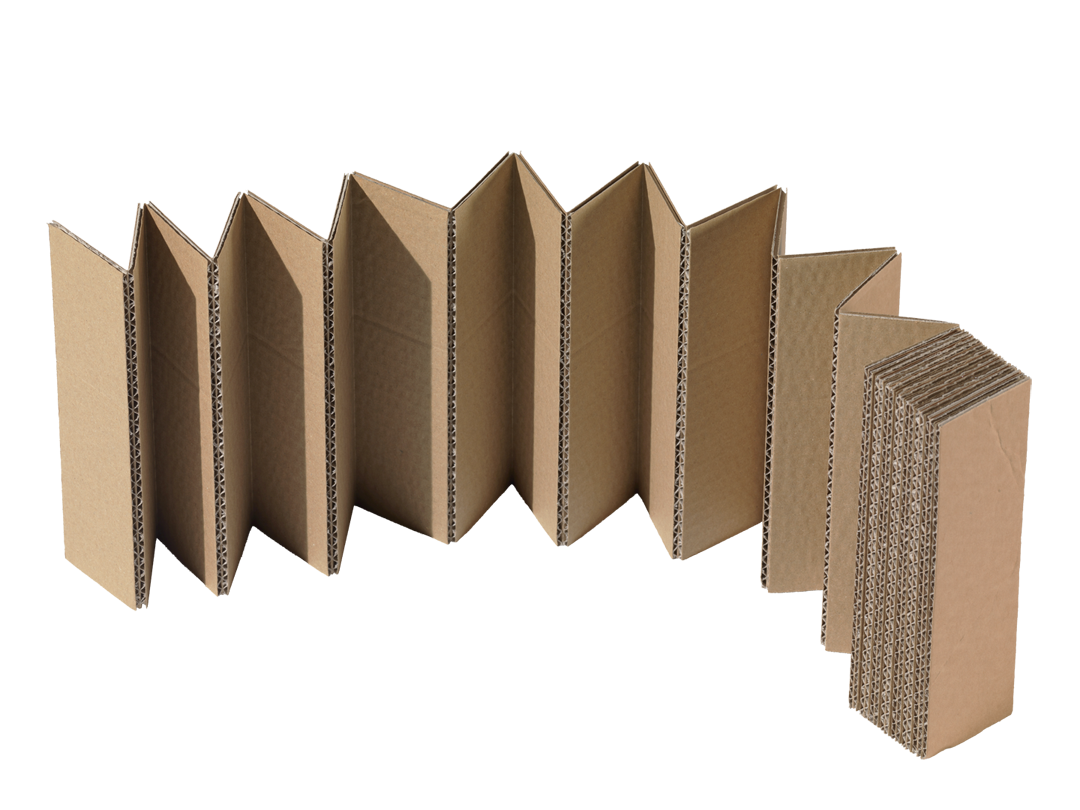

Uni.Co is a flexible machine capable of producing pads, partitions, reinforcements, internal protections, fillers and much more in solid and corrugated paperboard. Its flexibility is also displayed by the speed at which the size change takes place, easily possible thanks to the settings adjustment on the Touch Screen panel supported by a high-tech multimedia graphics.

The punching system adopted to produce partitions makes this cutting system the most compact overall. Thanks to the use of punching tools, the customer will no longer have to use die-cutting tables, which always require large spaces to be stored.

Technical Data

| Machine speed | up to 170 cuts/minute - depending on pieces size |

| Board width | max. 1400 mm (55 1⁄8”) |

| Distance between slitting | min. 35 mm (1 3⁄8”) |

| Crosscutting | min. 30 mm (1 3⁄16”) - max. 1600 mm (63”) |

| Partitions height | min. 38 mm (1 1⁄2”) - max. 420 mm (16 17⁄32”) |