Maximum efficiency is not synonymous of maximum speed

Today the search of innovative solutions in order to obtain maximum efficiency on production lines in bindery has become predominant and strategic.

An interesting case study is the analysis developed with our customer Legatoria Massarotto, historic Italian binder, one of the few companies that continues the production of quality books, following the market trends, but always being careful in achieving profitability and efficiency.

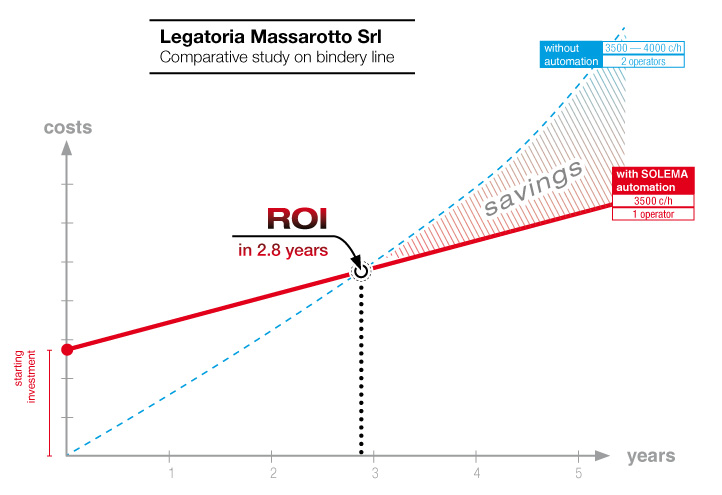

The focus is on a soft cover line that was running at a speed around 3500~4000 c/h, managed by two operators, always working there loading and unloading the line.

Massarotto management has developed with us a solution in order to make this working process more efficient. The new layout includes a book block feeder Fastbook & Autoload and a Pluton palletizer and this new configuration allows to entrust the whole line to only one operator, at a constant speed of 3500 c/h.

ROI previsions are calculated considering the particular kind of production and the working conditions and are then very clear. Considering the working shifts, the hourly cost and the variation due to inflaction, removing an operator means a saving on costs computable in about 80%. In less than 3 years, the investment will be fully recovered.

Solema automation brings always great benefits, starting from low production rates in little/medium companies; once the speed, the number of operations and working shifts increase, the ROI becomes more meaningful.

Offering reliable and competitive costs is the key to operate successfully in today's market.