We have met Stefano Angero, owner of Veronapack together with his brother Giovanni

The protagonist of this news is our long-term customer, Veronapack, a leading company in the production of corrugated and solid cardboard packaging, which over the years has also become a partner and a loyal ally of Solema.

Good morning Mr. Angero, please tell us who Veronapack is and what you do in your company?

Veronapack ( › link ) is a company located in Albaro di Ronco All’Adige (Verona) which produces high-quality paperboard dividers. Specifically corrugated and solid board partitions and spacers, ideal to protect and contain objects like bottles, jars and everything that needs special care in transport and storage processes, with the final aim of ensuring that the packaged product reaches its destination perfectly undamaged.

Born in 1989, Veronapack produces every year about 13 million partitions and 20 million pads. The production facility is equipped with 4 complete assembly lines and a flat-bed diecutter, that allow the realization of any type of partition, both for number of cells and for size. Our products are used in the most varied sectors, from wine to mechanics, from ceramics to pharmaceuticals.

In 2005, a warehouse of 2500 sqm was inaugurated in order to widen the range of partitions produced, culminating in 2008 with the acquisition of a third partition assembler, mod. Andax-Jumbo ( › link ), thanks to which Veronapack expanded its production to all types of corrugated board partitions – small, medium and large sizes.

The growth of the company continued in 2013 with the inclusion of the fourth production line with a Moser partition assembler ( › link ) and the introduction of solid board among the materials used for production, in order to serve properly the markets of wine and glass. In fact, since 2012, also following the acquisition of majority shares by the Angero family, Veronapack has definitively extended the business also to the solid board, thanks to the development of the wine and beverage market that in those years recorded an extraordinary increase.

2013 was a decisive strategic turning point that allowed us to take off in a market in which we figure among the most important realities in Italy and Europe.

What is your corporate mission?

“Always satisfy the customer in every request, even the most complex". I could summarize Veronapack mission in this way .

In an economic context such as the current one, production schedules, delivery times and product customization become important and crucial factors. It is therefore essential to know how to meet orders, increasing the level of technical skills and purchasing specific machinery with the aim of making the final product more and more effective and "customized". This is the secret that makes our corporate philosophy a reality.

You told us that 2013 has been the turning point year with the introduction of solid board partitions in your production. Could you please tell us why this has been a strategic choice?

From the beginning and until 2012 Veronapack produced only corrugated board partitions and separators mainly in standard models, ranging from small size ones, assembled by hand, to larger ones (140cm x 120cm) for the most varied markets, from automotive filters ( › link ) to recurrence cakes such as Italian traditional Christmas Panettone and Pandoro, which at that time involved a strong seasonality in the final months of the year, and worth alone around the 30% of Veronapack’s turnover.

For the corrugated board branch, we have always been Italian leaders for number of pieces produced every year. A perfect scenario, but which at the same time could dangerously lead to a stagnation of the market and to no more productive incentives within the company.

In 2013 we had the strategic intuition to focus the efforts on the development of a new productive division dedicated exclusively to solid board, this in order to expand the production range and diversify the business – alongside the corrugated one, made of limited and standardized runs.

Behind this choice there has been the fact that, although Italy had always been a wine producer and exporter, the partitions for this market have still been purchased in large quantity from abroad, in particular from France and Germany. After a careful examination, there was no large Italian companies to deal with this segment, so why not try to fit in? Veronapack wanted to grasp this opportunity.

At the moment the processing of solid board is not yet our core business, but the growth in these last 7 years is really significant: from 0.5% to more than 10%. And the prospects are interesting and promising.

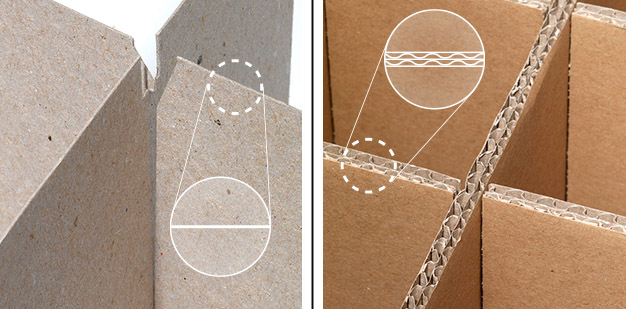

What is the difference between corrugated and solid board and which are the advantages of using the solid one?

The difference lies mainly in the absorption and vertical hold of the products inside the box. The use of solid board has increased the performances related to the safety of freight and storage of the boxes that the corrugated one could not ensure.

Differently from corrugated, solid board allows diversified productions, responding to what the market is asking for, allowing automatic packaging lines to make a quick opening of the partitions to fit on the products in the boxes thanks to its flat shape.

Solid board is also the result of environmental policies that support the waste separation, being generated by the recycling of waste paper. The entire production process – in addition to low energy use – is therefore "zero impact" on forests.

The main advantages of the solid board are mainly 3:

- Best quality/price offer

- Reduction of overall dimensions and optimization of the space inside the box.

- Maximum resistance for automatic high-speed bottling processes

The revolutionary aspect of the solid board consists especially in the convenience of transport, which favors long distances. A load of corrugated partitions, due to the specificity of the material, could have a component of ‘air’ (the volume created by the corrugated sheets waves) up to 60%. The typical maximum distance for transporting this type of dividers is around 150km; beyond that, transport costs are no longer justified.

On the other hand, a load of solid board partitions consists entirely of cardboard. For this reason, the typical maximum distance for the transport of corrugated ones (about 150km) no longer constrains the range of distribution. This is the main advantage of the solid board compared to the corrugated, because it guarantees considerable savings in time and costs allowing you to cover routes that were previously unthinkable, especially if we think of such heavy freights. In addition to this, the solid board partitions are suitable for the fast and systematic operations of opening and insertion in boxes, typical steps of automatic lines.

Not surprisingly, today, large part of the supply of solid board still comes from abroad. And we are talking about a sector that only in Italy currently produces 60 million partitions in a year.

Let’s take the example of a wine producer from South of Italy who needs to transport millions of bottles around Italy and Europe. Providing solid board dividers, Veronapack is now the right supplier, as the above mentioned cost issues no longer exist .

The solid board business also contributed to your meeting with Solema. Can you tell us exactly how it happened?

The meeting between us and Solema dates back to 2013, the year in which we purchased 4 new machines from Roda, which was at that time the only European reality in the production of machinery for the processing of corrugated and solid board. At the end of that year Roda’s property decided to sell the company branch of the machines for pads and partitions. Solema acquired it ( › link ), becoming the new owner of the designs and patents. We were then looking for a serious and competent company that would be able to follow us both in the maintenance and in the development of machines for cardboard processing, whereas – being the partitions market a niche one - there was a risk that such business would not prove to be profitable.

So can we consider this meeting as a “perfect matching”?

Yes, of course. We immediately took the opportunity, stating that Solema was the solid and professional supplier we were looking for. A partner that could give continuity and future to our project related to solid board, which was still developed mainly abroad, as in Italy there weren’t such large volumes to justify investments in machines, resources and know-how.

It was a real pity that in those years the biggest Italian wine producers had to turn to foreign companies to buy partitions. But now things are changing .

How has the collaboration with Solema continued over the years?

After the first intervention of Solema for the start-up of the 4 Roda machines (purchased just before the Roda-Solema deal), Veronapack needed to renew its range of machines. And so in a couple of years – about 2015 – we bought 2 new Solema machines. In 2018 and 2019 there were other important peaks with the installation of the Sol-Combi ( › link ) and then of the Super-Combi ( › link ), two machines that Solema has designed specifically for us, for our need to have a single phase of in-line processing instead of the traditional two-phase workflow. A perfect investment that allowed Veronapack to shorten production times, improving the operating flow and avoiding dispersion of time and money, giving also the possibility to create smaller runs without losing in terms of convenience, as required by the market .

With the arrival of Sol-Combi and Super-Combi, the workflow changed, becoming more flexible and dynamic and moving from long productions to smaller and always different runs: a trademark that has become a specific added value of our company.

The partnership with Solema has been strengthened over the years, and today in Veronapack there are 11 Solema branded machines, including 4 periodically revised Roda and 7 “new generation” ones.

----

But to build a successful partnership, it takes two. We have also involved Luca Parsani, CEO of Solema, in this conversation, asking him to tell us about the importance of the meeting with Veronapack.

The meeting between Solema and Veronapack is not a “every day meeting” in the history of a company. A particular connection was immediately created that led to the birth of a collaboration and partnership based on a common feeling, made of trust, professionalism and mutual esteem. A consolidated and durable relationship that allowed the two companies to improve each other, increasing competitiveness in the market and bringing benefits, both from the point of view of production and professional growth.

In 2013 we were already established in the field of the production of machines for the Graphic Arts, but our aim was to expand the business to other sectors. The meeting with Veronapack allowed us to enter the market of paperboard pads and partitions.

Veronapack was looking for a strong supplier to have the opportunity to invest and continue its business in this market, and so we found out that the common interest was to support each other in the classic relation do ut des: they gave something to us that, over time, we returned.

At the beginning of the work done on the 4 Roda machines, their help was fundamental in supporting us from a technological point of view, being our guide on-site and contributing to the perfect functioning of the machineries. When we met, Veronapack was a company in strong expansion and approaching to the delicate transition from a little craft company to a technology company, and the first machines we supplied in 2015 allowed it to make a big step forward in terms of production and turnover: it actually has passed from 2Mil. Euro to 3,3Mil. Euro, as well as the staff has doubled.

It was surprising to find out that there was a customer who could work, grow and profit just with our machines. At the same time, it was a big responsibility for us.

The excellent relationship between the two companies is so well-established that the production site of Veronapack is for us like a showroom, with always open doors to our customers who would like to be feel tangibly our technology. An example? In September 2015, during our Open House ( › link ), we organized special minibus to bring agents and customers from our headquarters in Pedrengo to Albaro di Ronco All'Adige, in order to show them our machines in action throughout the entire production cycle. The event was attended by people from all over the world, as Korea and United States. The event was a success, enriched by a suggestive visit in the city of Verona.

In conclusion, I would like to underline how the collaboration with Veronapack has contributed to develop the idea of Solema Service Pack ( › link ), our Customer Care offer ( › link ) that includes Preventive Maintenance programs ( › link ). Veronapack was among the first of our customers to sign a contract for a part of the services related to the Remote Service Tool ( › link ), the innovative tool of Solema Customer Care.

----

Stefano Angero, after our talk, told us that Veronapack is currently finalizing an important contract for a leading producer in the beverage sector for the production of 11 million of solid board partitions. We will tell you the details of this important project in one of the next newsletters. So, stay tuned!

To have more info about Solema write to info@solema.it or call +39 035 654111.